The fishing industry on the West Coast holds immense importance, not just for the local economies and communities but also for the cultural fabric of the region. The fisherman’s life is deeply intertwined with diverse cultural influences that have shaped the industry over the years.

Intro

The West Coast fishing industry has long been a vital economic driver for the region. It provides employment opportunities, supports local businesses, and contributes to the overall economic prosperity of coastal communities. Furthermore, the industry plays a crucial role in supplying fresh seafood to local and international markets, making it an essential component of the food supply chain.

The fisherman’s life is not just about the catch. It is a way of life deeply rooted in cultural traditions. The West Coast fishing industry has been shaped by the contributions of various cultural groups, including First Nations, Chinese, Japanese, and Indo-Canadians. These diverse influences have not only enriched the industry but also fostered a sense of multiculturalism within the fishing community.

Evolution of the West Coast Fishing Industry

The evolution of the West Coast fishing industry is a fascinating tale of diverse influences and significant historical events. From the early beginnings shaped by First Nations’ traditional fishing practices to the profound impact of Chinese laborers and the challenges faced during Japanese internment, this section explores the transformative journey of the industry.

The fishing industry on the West Coast has its roots in the traditional practices of First Nations communities. For centuries, these indigenous groups developed sustainable fishing techniques that honoured their deep connection to the land and sea. First Nations’ fishing methods often varied based on the specific coastal regions they inhabited, with each community contributing unique knowledge and expertise.

The cultural significance of fishing is reflected in the halkomelem words, the language of the Coast Salish people. Halkomelem is rich in vocabulary related to fishing, reflecting the importance of this activity in the lives of First Nations communities. These words not only describe various species of fish but also convey the spiritual and cultural significance attached to fishing practices.

First Nations’ Contribution

First Nations’ contribution to the West Coast fishing industry extends beyond their traditional practices. They have played a crucial role in shaping the industry’s development and success. Through their deep understanding of the ocean and their sustainable fishing methods, First Nations communities have set the foundation for responsible fishing practices that continue to be followed today.

Moreover, First Nations’ cultural knowledge, including their intricate understanding of the ecosystem and their respect for marine life, has influenced conservation efforts within the fishing industry. Their wisdom and stewardship have contributed to the long-term sustainability of fish stocks and the preservation of coastal ecosystems. Today, foe example, we know about Namu in BC that is a small fishing port located on the coast of the province. It has a rich history as a former cannery town and is also home to a First Nations community.

Labour Union in British Columbia (BC)

In addition to the significant contributions of First Nations communities to the fishing industry in British Columbia, the role of labour unions cannot be overlooked. Labour unions have played a crucial part in advocating for the rights and well-being of workers in the fishing sector.

The efforts of labour unions have resulted in significant advancements in the fishing industry. Improved safety regulations, including proper training and equipment, have helped to protect workers from hazards at sea. Union representation has also empowered workers to address workplace issues and grievances effectively.

Chinese Laborers and the Canadian Pacific Railway

The construction of the Canadian Pacific Railway (CPR) in the late 19th century brought thousands of Chinese laborers to the West Coast. These hardworking individuals played a vital role in connecting the East and West of Canada as they worked under challenging conditions to lay the railway tracks across rugged terrain.

The Chinese laborers faced numerous hardships, including hazardous working conditions, discrimination, and unequal pay. However, their unwavering dedication and resilience were instrumental in completing this monumental project, which had far-reaching implications for the region’s development.

Beyond their contributions to the construction of the CPR, Chinese immigrants also made significant contributions to the West Coast fishing industry. Chinese butchers, in particular, brought innovative techniques and skills to the processing and preservation of fish and seafood.

Chinese butchers introduced the “iron butcher,” a specialized tool used for filleting and preparing fish. This revolutionary tool improved efficiency and precision, leading to higher-quality products and increased productivity within the fishing industry. The techniques and knowledge introduced by Chinese butchers have left a lasting impact on the West Coast fish processing methods.

Japanese Internment during World War II

The outbreak of World War II had a devastating impact on the Japanese-Canadian community, many of whom were actively involved in the fishing industry. Following the attack on Pearl Harbor, the Canadian government implemented policies that resulted in the forced relocation and internment of Japanese Canadians.

Japanese Canadians, including fishermen and their families, were unjustly uprooted from their homes and businesses and forcibly relocated to internment camps. This disruption caused significant loss and hardship within the fishing community, as their livelihoods were abruptly taken away. The fishing boats, equipment, and infrastructure they had painstakingly built over the years were left behind or confiscated.

Indo-Canadian Immigration and Its Impact

In the wake of World War II and the Japanese internment, a new wave of immigration swept through the West Coast, bringing a fresh infusion of cultural diversity. Indo-Canadians, particularly from the Punjab region, began immigrating to Canada, seeking new opportunities and a better life.

Indo-Canadian immigrants played a vital role in revitalizing the fishing industry and filling the void left by the interned Japanese Canadians. They brought their skills, knowledge, and work ethic to the industry, contributing to its growth and transformation. Indo-Canadians played a crucial role in the development of fishing-related businesses, such as boat building and seafood processing, and continue to be an integral part of the West Coast fishing community.

Life of a West Coast Fisherman

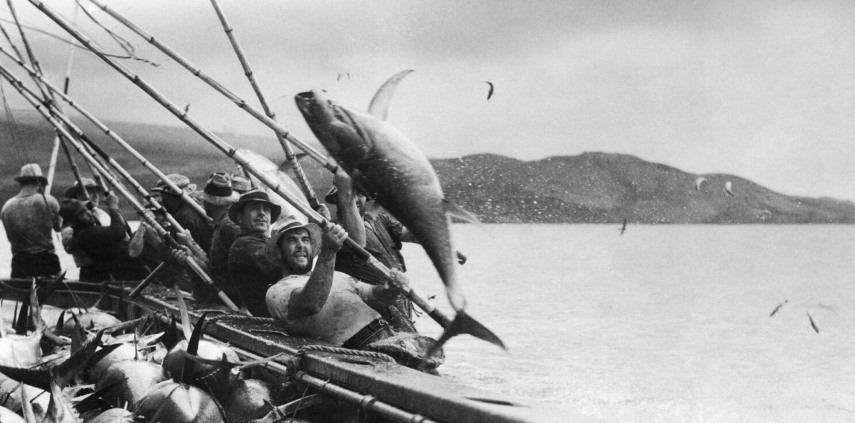

Herring skiffs, traditional fishing boats used on the West Coast, hold historical significance. These small, nimble vessels were specifically designed for herring fishing and played a crucial role in the region’s fishing practices.

Technological advancements have transformed the fisherman’s life, with the introduction of the automatic crab butchering machine being a notable example. This innovation streamlined the crab processing process, increasing efficiency and reducing manual labour.

Fish Cannery Jobs

Fish canneries were bustling centers of activity, employing a diverse workforce. From filleting fish to operating machinery, the various roles within a fish cannery were essential for the efficient processing and packaging of seafood.

The canning vacuum pump revolutionized the fish canning process, allowing for the preservation of fish and seafood in airtight containers. This advancement extended the shelf life of canned products, ensuring their safe transport and availability to consumers.

BC Packers and the Steveston Cannery

BC Packers, along with its predecessor companies, has a rich history intertwined with the West Coast fishing industry. From its early beginnings in the late 1800s to its emergence as a leading fish processing company, BC Packers played a significant role in shaping the industry.

The Steveston Cannery, once a thriving hub of activity, experienced both prosperous and challenging times. From its establishment as the Imperial Cannery to its decline and eventual closure, the rise and fall of this iconic cannery reflect the changing dynamics of the West Coast fishing industry.

Cultural Diversity in the Fishing Community

The fishing community on the West Coast is a testament to the power of diversity and multiculturalism. People from various ethnic backgrounds, including First Nations, Chinese, Japanese, and Indo-Canadians, have come together, contributing their unique skills and perspectives to shape the fisherman’s life.

Diverse Ethnic Groups Working Together

The West Coast fishing industry thrives on the contributions of diverse ethnic groups. First Nations communities, with their deep connection to the land and sea, bring traditional knowledge and sustainable fishing practices to the industry. Their cultural heritage and respect for the environment have influenced fishing methods and conservation efforts.

Chinese laborers, with their expertise in fish processing and preservation, have played a crucial role in improving efficiency and productivity within the fishing industry. Their innovative techniques, such as the iron butcher, have transformed fish processing methods and contributed to the industry’s growth.

Japanese Canadians, despite the challenges they faced during internment, made significant contributions to the fishing community. Prior to internment, they were active participants in the industry, operating fishing boats, canneries, and related businesses. Their skills and knowledge helped shape the fishing practices and infrastructure on the West Coast.

Indo-Canadians, who arrived in Canada after World War II, brought their entrepreneurial spirit and work ethic to the fishing industry. They established businesses, including seafood processing plants and boat-building operations, adding a new dimension to the industry’s diversity and growth.

Role of Multiculturalism in Shaping Fisherman’s Life

Multiculturalism is a defining aspect of the fisherman’s life on the West Coast. The blending of cultural traditions, practices, and cuisines has created a vibrant and inclusive community. This multicultural environment fosters understanding, respect, and cooperation among individuals from different backgrounds, resulting in a shared sense of purpose and camaraderie within the fishing industry.

The exchange of ideas and the integration of diverse perspectives have led to innovation and continuous improvement in fishing practices. The fisherman’s life is enriched by the cultural tapestry woven through the contributions of diverse ethnic groups, making it a unique and dynamic community.

Women in the Fishing Industry

Indo-Canadian women have played a significant role in the fishing industry, challenging traditional gender roles and making their mark. In the past, women’s involvement in fishing was limited to supporting roles, such as bookkeeping and administration. However, Indo-Canadian women have broken barriers and taken on more prominent roles within the industry.

Indo-Canadian women can be found working as fishers, operating boats, and even managing their own fishing businesses. Their determination and passion have paved the way for greater inclusivity and gender equality within the fisherman’s life.

In recent years, the fishing industry has witnessed a shift in the roles and perspectives of women. More women are entering the industry, not only as fishers but also in leadership and decision-making positions. They bring diverse skills, knowledge, and fresh perspectives that contribute to the industry’s growth and adaptability.

Impact of the West Coast Fishing Industry

The West Coast fishing industry has a profound impact on local economies and communities. It provides employment opportunities, stimulates tourism, and supports related industries such as seafood processing, boat building, and marine services. The industry’s economic contributions are vital for coastal communities, generating income and fostering economic stability.

Preserving the history and heritage of the West Coast fishing industry is essential to understanding its cultural significance and ensuring its legacy endures. Institutions like the City of Richmond Archives play a crucial role in collecting, preserving, and sharing historical materials related to the fishing industry. The archives provide valuable resources for research, education, and public engagement, ensuring that the stories and experiences of the fisherman’s life are accessible to future generations. Additionally, organizations like Ladner Motors and Big Iron Mechanical are dedicated to preserving fishing machinery and equipment. They recognize the value of these artifacts in telling the story of the industry and work diligently to maintain and restore them.